FARMPIPE SN6

Rural/Forest

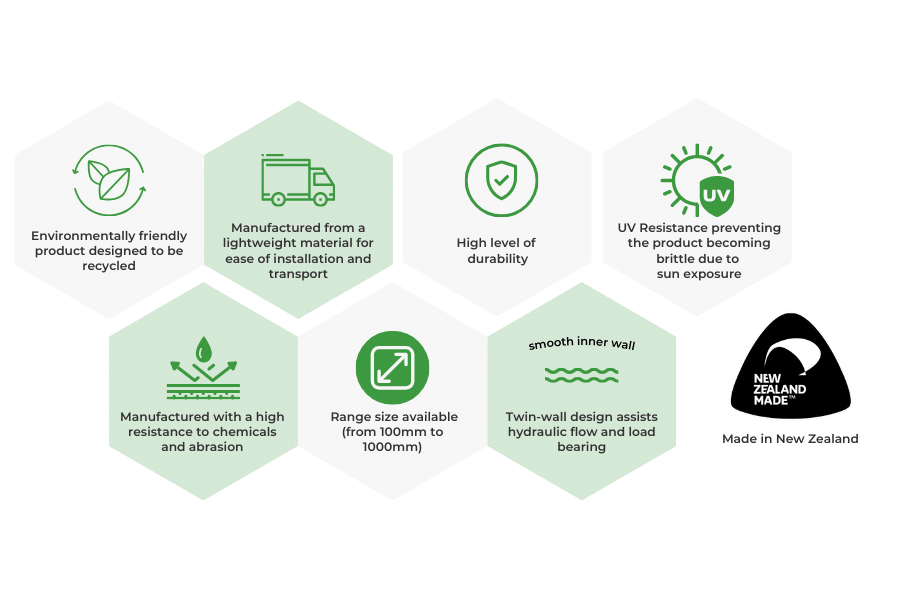

Our modern, strong and durable Rural/Forestry Culvert Pipes are New Zealand-made and manufactured from polyethylene with an extruded twin-wall design to tackle your needs.

LIGHTER | STRONGER | LONGER

- Request a Quote

- Call us: 09 869 3030

- Email: [email protected]

- Office: 3 Averton Place East Tamaki Auckland 2013

Quality Assured

INFRAPIPE™ is ISO 9001 and ISO TYPE 5 certified to ensure consistent reliability and quality management.

- Our locally manufactured Rural/Forestry Culvert Pipes have an SN8 rating with an ID size range from ID 100mm to ID 1000mm.

Please ask for our civil pipes for a higher SN rating and twin-wall design.

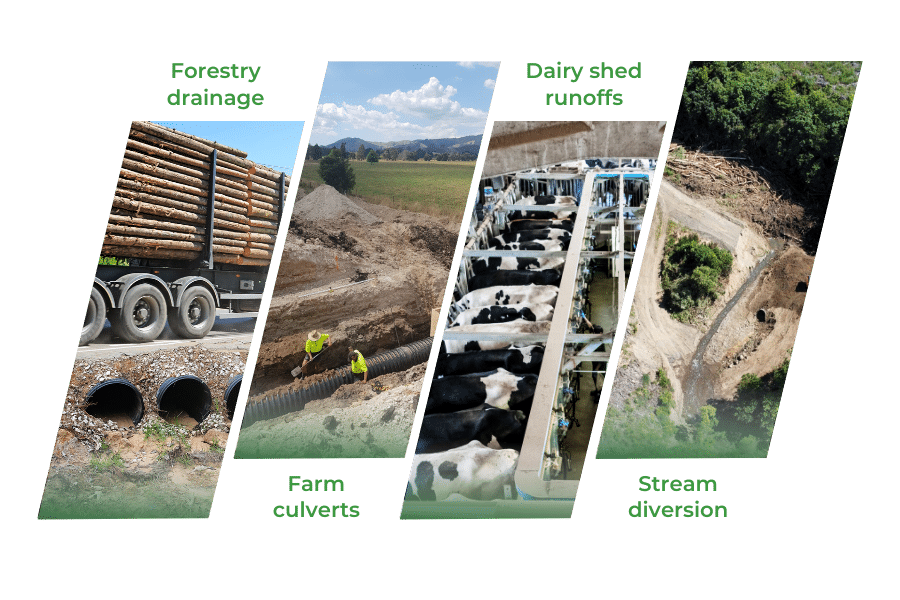

Applications

INFRAPIPE™ Rural/Forestry Culvert Pipes are manufactured to SN6 ratings.

Transportation & Handling

INFRAPIPE™ Rural/Forestry Culvert Pipes are manufactured to SN6 ratings.

- INFRAPIPE™ Rural/Forestry Culvert Pipes are designed and manufactured to be lightweight, with a twin wall construction that minimizes the need for heavy lifting equipment. If required, these pipes can be transported on utility vehicles using roof racks and in small trailers for added convenience.

- The lightweight nature of FARMPIPE allows it to be handled by two people while maintaining its high durability. This product offers significant savings in time, machinery, labour and therefore overall cost.

- FARMPIPE pipes are normally supplied in packets for easier handling of volumes. See the table for packet sizes for your required diameters.

Please refer to our Freight and Delivery Policy for more details about transportation.

INFRAPIPE™ Rural/Forestry Culvert Pipes are designed and manufactured to produce zero toxic leaching.

As part of our commitment to sustainable manufacturing, this product range considers environmental factors. Our Rural/Forestry Culvert Pipes are fully recyclable and help us promote closed-loop manufacturing cycles.

Installation

FARMPIPE is lighter than concrete pipes. This makes the installation easier, safer and more efficient.

Embedment material should be AP or GAP 7, 10, 20 or 40. The minimum dimensions for installation are as follows:

Dimension | mm | Notes |

Cover Height | 600 | From top of pipe to ground level |

Base embedment | 150 | From native soil to base of pipe |

Side embedment | 150 | From native soil to side of pipe |

Trench Width | Pipe OD plus 300 | |

Trench Depth | Pipe OD plus 750 |

Pre-Installation

Pre-Installation Inspection

Inspect the pipes and look for any defects or damages that may have happened onsite, prior to installation, internally and externally. If you have purchased a Rubber Ring supplied by INFRAPIPE™ it should stay in its sealed packaging until fitted.

- Rubber rings are to have no cuts, weather damage, or dislodgement that could affect the overall performance of the pipe.

- All pipeline jointing/connections shall have no defects or damage that could affect the overall performance of the pipe.

These steps outline the correct way to push FARMPIPE pipes together while in a trench and they are:

Step 1 Before lifting the pipes into the trench, position the pipes so that the pipe ends are easily accessible. Ensure the bedding material is laid at the correct grade before putting the pipe in. |

Step 2 Pipes should be aligned along the trench and continuously supported by bedding material. |

Step 3 Check the socket and spigot end for any damages that may have occurred onsite while wiping them free of debris and dirt. |

Step 4 On the spigot, identify the witness mark which indicates the depth the spigot is to be pushed into the socket. |

Step 5 At this point, the rubber rings can be installed onto the cleaned spigot end and positioned them in the groove. |

Step 6 Apply pipe lubricant to the socket. Do not apply lubricant to the spigot ends as it can cause the rubber rings to slide out of their grooves. INFRAPIPE™ can supply this if necessary. |

Step 7 Lift the pipe into the trench. Place it into position and ensure the alignment is correct. It is important to make sure the pipes are correctly aligned to each other to prevent jamming. |

Step 8 Push the spigot end into the socket and up to the witness mark. A heavy-duty crowbar can be used on small diameter pipes. |

RUBBER RINGS

NZ-Made 100yr life rings are available for joining pipes

FLUMING

Single-wall half-pipe variants are available

HALF LENGTHS

Are available on request.

RUBBER RINGS

SN6 Codes

Product and Rubber Rings Codes

PIPE DN | PRODUCT CODE | RUBBER RING CODE |

100 | TW6.100.6 | TWR.100 |

150 | TW6.150.6 | TWR.150 |

225 | TW6.225.6 | TWR.225 |

300 | TW6.300.6 | TWR.300 |

375 | TW6.375.6 | TWR.375 |

450 | TW6.450.6 | TWR.450 |

525 | TW6.525.6 | TWR.525 |

600 | TW6.600.6 | TWR.600 |

800 | TW6.800.6 | |

1000 | TW6.1000.6 |

SN6 Dimensions and Weight

INFRAPIPE™ Rural/Forestry Black Culvert RRJ Pipes are manufactured to SN6 ratings.

PIPE DN | PRODUCT CODE | ID (INSIDE DIAMETER) | EFFECTIVE LENGTH | OVERALL LENGTH | PACKET CONTAINS | OD (OUTSIDE DIAMETER) | WEIGHT (KG) |

100 | TW6.100.6 | 98 mm | 6413 mm | 6490 mm | 30 | 115 mm | 4 |

150 | TW6.150.6 | 147 mm | 6348 mm | 6461 mm | 23 | 171 mm | 6 |

225 | TW6.225.6 | 218 mm | 6283 mm | 6429 mm | 6 | 252 mm | 14 |

300 | TW6.300.6 | 295 mm | 6188 mm | 6389 mm | 6 | 343 mm | 22 |

375 | TW6.375.6 | 375 mm | 6188 mm | 6390 mm | 2 | 436 mm | 40 |

450 | TW6.450.6 | 450 mm | 6123 mm | 6340 mm | 2 | 521 mm | 61 |

525 | TW6.525.6 | 525 mm | 6041 mm | 6317 mm | 2 | 609 mm | 70 |

600 | TW6.600.6 | 600 mm | 5920 mm | 6273 mm | 1 | 698 mm | 90 |

800 | TW6.800.6 | 800 mm | 5936 mm | 6272 mm | 1 | 932 mm | 161 |

1000 | TW6.1000.6 | 1,000 mm | 5892 mm | 6283 mm | 1 | 1166 mm | 258 |

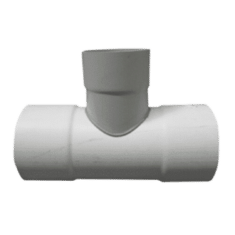

Fittings

A full range of matching fittings is available, ask your supplier for details and pricing. Fittings available are T junctions, Y junctions, Manhole connectors, End caps, Bends (90,45,22,11), Couplers, reducing Ts, reducing Ys and saddles.

Ask for made to order DN1000-DN3200

Product Attributes & Benefits

FARMPIPE combines strength, performance, quality, longevity and exceptional durability.

FARMPIPE SN6 Culvert Pipe

FAQs

What are the advantages of FARMPIPE SN6 pipes compared to your competitors?

FARMPIPE SN6 pipes offer superior performance, quality, and exceptional durability.

Why should I choose FARMPIPE SN6 over other alternatives?

FARMPIPE SN6 pipes are a better value for your money.

- FARMPIPE SN6 pipes are the best solution for optimizing your project budget without compromising quality.

- Choosing our dual-rated pipes provides versatility and cost-effectiveness.

- So, why settle for less when you can have the best? Choose our SN6 pipes and get the job done right!