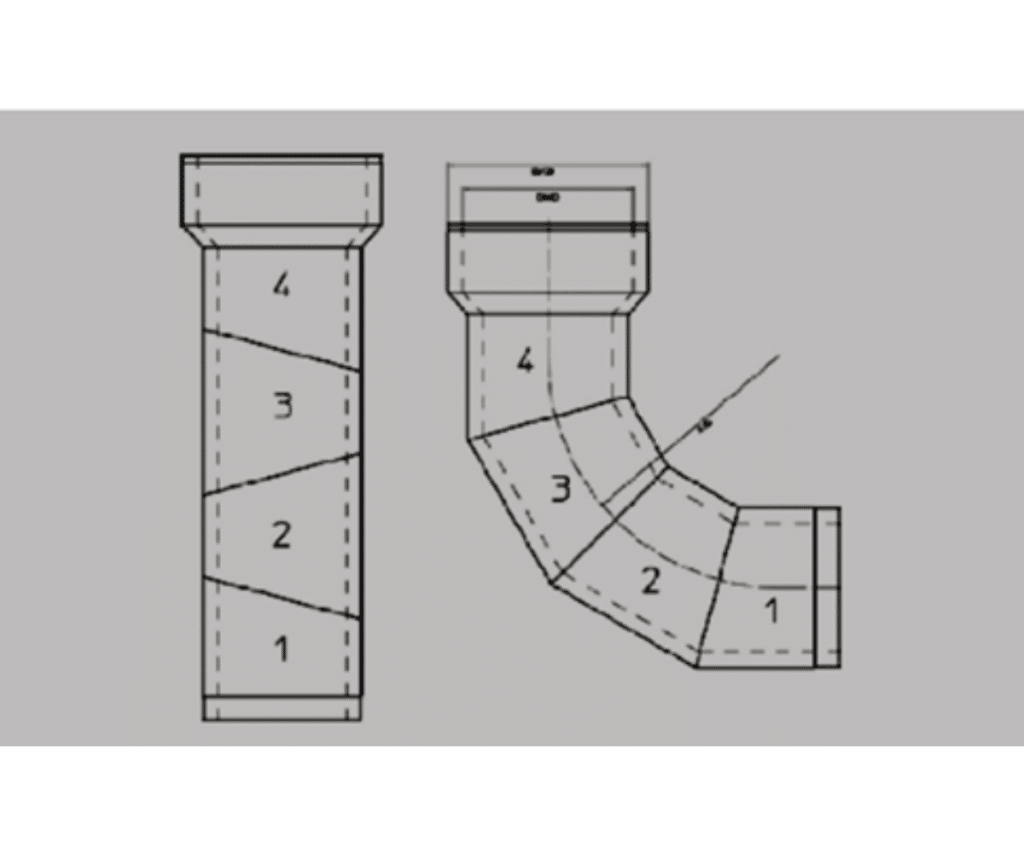

BENDS & RISERS

INFRAPIPE can easily create a bend or riser with any angle and with any radius (greater than 1.5 * diameter). A portion of the pipe is cut and then extrusion welded internally and externally. This process can be repeated for uncertain subsurface conditions, these can be even be cut to order after a site survey – measure one morning and the bend ships the next day.

- Request a Quote

- Call us: 09 869 3030

- Email: [email protected]

- Office: 3 Averton Place East Tamaki Auckland 2013

This liberates design engineers and asset owners from having to adapt the site to the constraints of designing in straight lines from one manhole to the next. Pipes can easily be curved around other services, structures, obstructions, grade changes or even trees to adapt to the best use of the site and minimize construction cost.

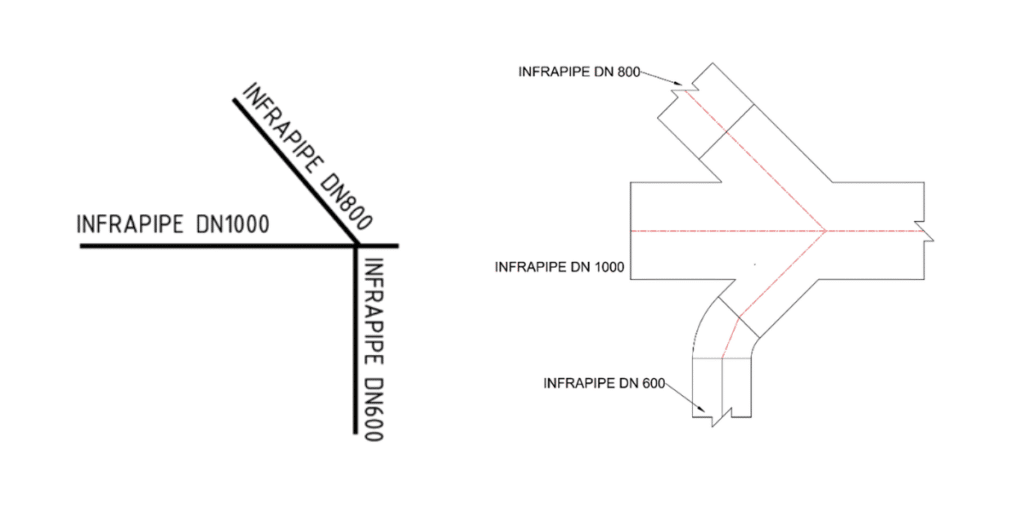

Additionally, bends can be used to optimize hydraulic efficiency – in the example shown below a lateral arriving perpendicular to the main channel is diverted before the connection to a more efficient 45-degree angle to the flow, reducing the impact of the arriving fluids on the hydraulic performance. Again, this can be done with any angle in any way.

Using bends to reduce the cost of manholes is complemented by the ability to offer access without any impact on hydraulic efficiency. Access points – typically of DN/ID 600 or 1000 – can be added at any point (even a bend) to allow for manual inspection. These are provided centrally on pipelines up to approx DN1500 and then tangentially for larger pipes, which reduces the vertical distance and optimizes hydraulic performance.