Large Pipes, Large Tanks and Large Manholes

INFRAPIPE manufactures very large pipes in New Zealand, find out more here:

- What is a large pipe?

- Who makes the largest pipes in NZ?

- Why do people need large pipes?

- How do INFRAPIPE make the largest pipes in New Zealand and Eastern Australasia?

- Large tanks are made of large pipes

- Large manholes are made of large pipes

- What is different with large pipes?

- Are large pipes strong?

- How does size affect flow rate?

- Are large pipes cheaper than small pipes?

- Are large pipes heavy?

- Are large pipes certified?

- Are large pipes safe?

- How are large pipes transported?

- Are fittings available for large pipes?

- Who uses large pipes?

- Who else make large pipes?

Download more information:

- Request a Quote

- Call us: 09 869 3030

- Email: [email protected]

- Office: 3 Averton Place East Tamaki Auckland 2013

What is a large pipe?

- A large pipe is also known as a big pipe, a very large pipe, a massive pipe, a huge pipe, a giant pipe or a colossal pipe.

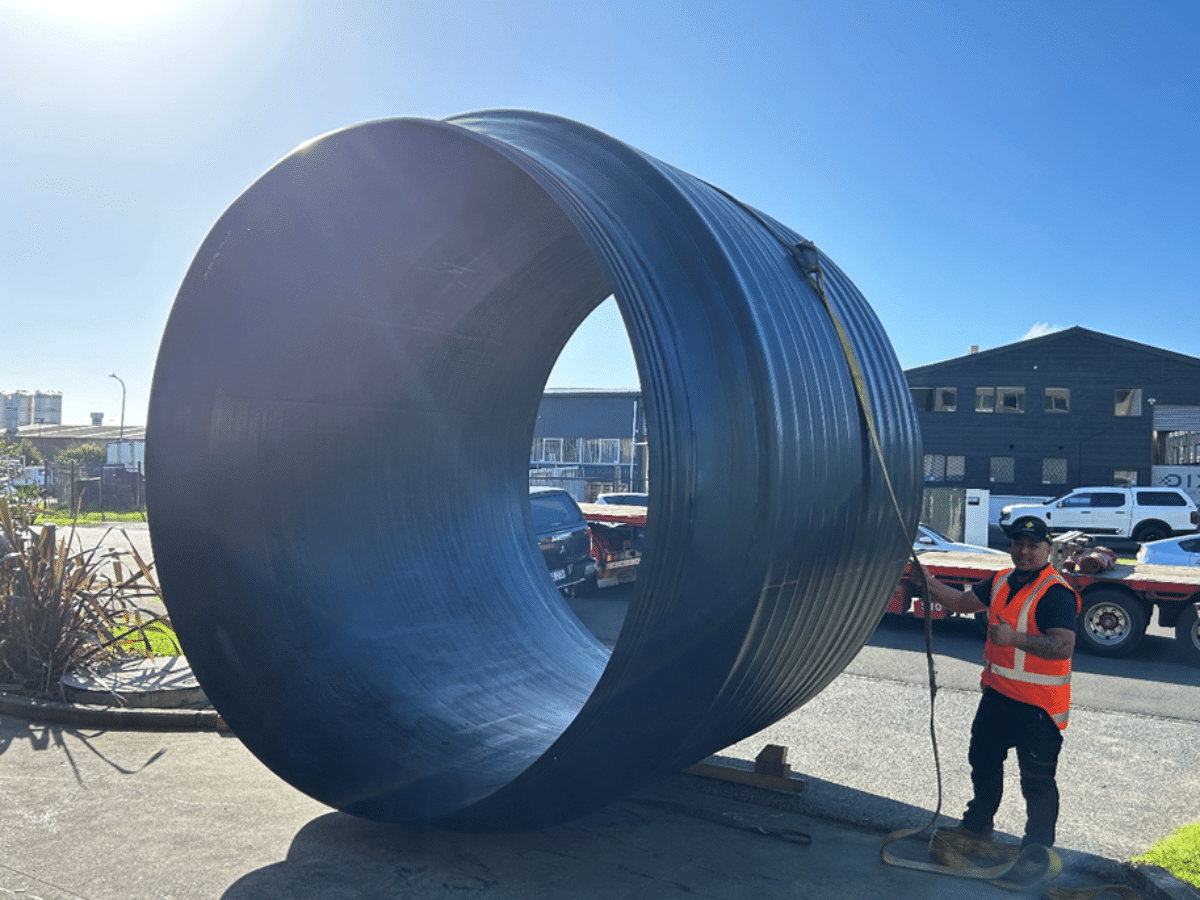

- Large pipes typically refer to pipes that are bigger than a human, so for INFRAPIPE that is the 2m, 2.3m, 2.5m and 3.2m diameter pipes.

- A 3.2m pipe has a cross sectional area of over 8m²!

- These pipes are also used to make big tanks, huge tanks, massive tanks and colossal tanks.

- Thermoplastics – HDPE & PP – are used to make the biggest pipes as they are lighter, easier to manufacture, safer and better for the environment.

- All pipes made by INFRAPIPE are great, not just the big ones.

Who makes the largest pipes in NZ?

The Colossus by INFRAPIPE is a DN3200 – that’s 3.2m in Inner Diameter.

This is the biggest pipe made in New Zealand and in Eastern Australasia.

Why do people need large pipes?

- Price – up to 50% cheaper for the same flow rate

- Lower flow velocity for a given flow rate

- Fish Passage – Bankful Width requirements

- Capacity – they need a large flow rate

- Convenience – only one pipe to inspect

- Reliability – reduced chance of blockage

- Future capacity predictions are volatile – providing future proofing

- Less space required horizontally for a given volume

- Environmental impact less per m³

- They just want a bigger pipe than someone else

How do INFRAPIPE make the largest pipes in New Zealand and Eastern Australasia?

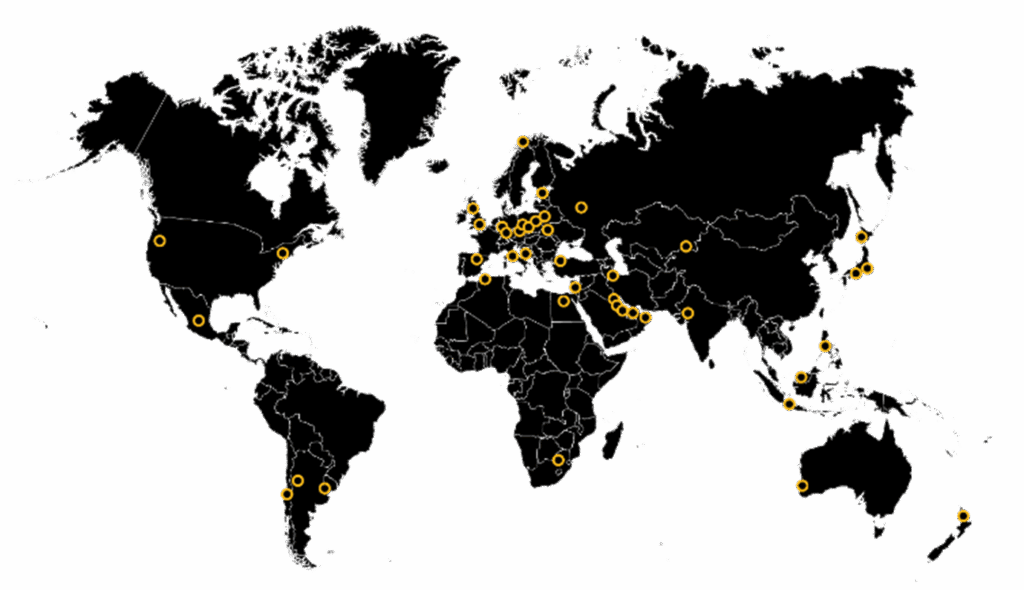

The biggest and best pipes are made in HDPE using a ![]() machine, which helically winds extruded PE onto a rotating mandrel, then a layer(s) of reinforcing tube to provide compressive strength and then for larger or stronger applications an additional restraining layer of PE. As shown below this technology is used globally to make very large pipes and tanks.

machine, which helically winds extruded PE onto a rotating mandrel, then a layer(s) of reinforcing tube to provide compressive strength and then for larger or stronger applications an additional restraining layer of PE. As shown below this technology is used globally to make very large pipes and tanks.

Large tanks are made of large pipes

HDPE tanks are made of sections of HDPE pipe so they can be made as big as you need. Further below on the page is a very very big tank – 8,050 m³, though we haven’t got this big in New Zealand yet.

Large tanks are used for fire and sprinkler supply, stormwater attenuation and wastewater storage and are available in sizes up to 1000m³+ and in diameters of 2m, 2,3m, 2.,5m and 3.2m.

A large fire supply tank below in 2.5m in the Manawatu and a large wastewater tank in 3.2m in the Waikato to the right.

Table 1 Large tank volumes

DN(ID) | m³/m | Pipe length - volume m³ | ||||||

5.8 | 11.6 | 17.4 | 25 | 40 | 50 | 100 | ||

2000 | 3.14 | 18 | 36 | 55 | 79 | 126 | 157 | 304 |

2300 | 4.15 | 24 | 48 | 72 | 104 | 166 | 208 | 416 |

2500 | 4.91 | 28 | 57 | 85 | 123 | 197 | 245 | 490 |

3200 | 8.04 | 47 | 93 | 140 | 201 | 321 | 402 | 804 |

Large manholes are made of large pipes

Large pipes are used in a vertical orientation to make large manholes, large pump chambers, large wetwells, large dry wells and large valve chambers. Not only are they enormously lighter than concrete (by a factor of 10), but often what has to be a 3m diameter concrete structure only needs to be 2m in diameter with HDPE because the structural integrity is unaffected by the penetrations.

For concrete, the removal of the reinforcing means that connections must be separated, and their size and number is limited. There is no such restriction for HDPE, so you do not always require a large manhole!

The example to the right is for stormwater at Auckland airport.

What is different with large pipes?

- Installation can demand more precision. In some applications, installers use pins (bolts) to assist (the installation here was pinned for instance).

- The pipe and trench is deeper.

- Craneage distances change (but weight at distance is still a fraction of concrete or GRP).

- Access is often easier to incorporate and less disruptive.

- The permissible deflection of the pipe is less as the ID increases (the radius of a deflected bend is a product of the ID).

- There is a greater likelihood of buoyancy which can be mitigated with a variety of methods.

Are large pipes strong?

Large pipes are just as strong as smaller pipes. The pipe shown here is a mighty SN43 for use in a Class A dam installation in the Bay of Plenty. INFRAPIPE calculates the pipe strength required – even 25 metres under a railway embankment – and designs a pipe profile to match.

How does size affect flow rate?

Massively! The reduced drag from the effects of the perimeter improves the hydraulic performance substantially – in the examples here, the HDPE DN3200 at 1:100 achieves a flow rate per m² of cross-sectional area of 9.75 (m³/s per m²) as opposed to 8 for the DN2500. Note also the 20%+ increase in performance from the smoother HDPE to the rough concrete!

Table 2 Flow rates for a given gradient, ID and material

Flow Rate m³/s | 1:200 | 1:100 | |

HDPE | DN3200 | 54 | 78 |

Mannings 0.011 | DN2500 | 28 | 40 |

Concrete | DN3200 | 45 | 64 |

Mannings 0.013 | DN2500 | 23 | 33 |

NZ Building code, NZTA & KiwiRail all specify Mannings n of 0.011 for HDPE and 0.013 for concrete. For more details see INFRAPIPE Mannings Graphs here.

Are large pipes cheaper than small pipes?

Yes, large pipes are cheaper per volume of water flow than small pipes. A DN3200 for instance, gives you 50% more Cross-Sectional Area per dollar than a DN1000.

Table 3 Equivalent capacities of large pipes

DN(ID) equals | Equivalent to | |

2 of ID | 3 of ID | |

2000 | 1350 | 1200 |

2300 | 1600 | 1350 |

2500 | 1800 | 1500 |

3200 | 2000 | 1800 |

Are large pipes heavy?

Not as heavy as you might think – the largest pipe in New Zealand an INFRAPIPE DN3200 is only 472kg/metre in SN4.

Table 4 Weights for HDPE SN4 pipes 6m long and Class 2 concrete pipes 2.5m long

INFRAPIPE 6m long | Concrete 2.5m long | |||

Size | kgs | Size | kgs | |

3200 | 2,832 | |||

2500 | 1,454 | |||

2300 | 1,177 | 2400 | 9375 | |

2000 | 827 | 2100 | 7125 | |

Although the sizes don’t match exactly, the weight difference per metre between concrete and INFRAPIPE is between 16 and 20 times!

For the contractor installing 2500, it’s the difference between lifting 9.3 tonnes of concrete 17 (seventeen) times, or just lifting 1.5 tonnes of INFRAPIPE 7 (seven) times. That’s a big saving in time and equipment costs!

Are large pipes certified?

Yes, INFRAPIPE has ISO9001:2015 and pipes are certified to AS/NZS5065:2005.

Are large pipes safe?

Large pipes are as safe as anything that big can be. The reduced weight of HDPE large pipes is a significant improvement in safety on site and especially in the trench. As the video below shows, their flexibility also reduces the likelihood of costly damage on site.

How are large pipes transported?

Large pipes can be transported in smaller sections to more easily meet maximum load width restrictions. Due to their lightweight even the largest INFRAPIPE pipes are easily transported and secured just like smaller pipes.

Large pipes can be transported in smaller sections to more easily meet maximum load width restrictions. Due to their lightweight even the largest INFRAPIPE pipes are easily transported and secured just like smaller pipes.

Are fittings available for large pipes?

Customised fittings like bends and access risers, connections, manholes, laterals, joins, risers and sumps are manufactured for a DN3200 just like they are for a DN1000. See above the integrated lateral into the riser and below, a large riser for Ports of Auckland.

Who uses large pipes?

Large pipes are needed everywhere there are large volumes of fluid to move, particularly.

- Forestry (as shown)

- Airports

- Ports and container handling areas

- Wastewater treatment and storage

- Urban development stormwater

- Instead of concrete mixing boxes

Who else make large pipes?

Our KRAH™ friends in Argentina make the largest HDPE pipe in the world at 3.6m. The picture below is the world’s largest solid wall pipe, a DN3600 with a wall thickness of 220mm, serving a water treatment plant in Buenos Aires that supplies more than 3 million people. In places the pipe is under 40m of water!

Our KRAH™ friends in Manila make DN3500, seen below is the restitution of a collapsed box culvert through several kilometres of busy highway. Note how small the working area is (and therefore how minor the disruption) – just 6m * 20m – room for 2 diggers and a crane, advancing 12m/day. The pipes are delivered to site on a trailer behind a ute!

Our KRAH™ friends in North America made the largest HDPE tank in the world at 8050m³ for stormwater attenuation in Canada from DN3500 pipe.

Our KRAH™ friends in Egypt supplied large pipes of numerous sizes to the worlds largest desalination plant at Bahr el Baqar.

Large pipes can also be known as epic pipes, monstrous pipes, mighty pipes, monster pipes, enormous pipes, mega pipes, jumbo pipes, voluminous pipes, substantial pipes, oversize pipes, gigantic pipes or mammoth pipes.