Sustainability

INFRAPIPE assists asset owners and their contractors to meet their environmental stewardship goals in the following manner:

- By offering a product which is completely recyclable.

- By reprocessing all production waste.

- By consuming recycled product where permitted by the standards.

- By manufacturing in New Zealand rather than shipping pipes from the Northern Hemisphere.

- By offering a product which minimizes freight from the factory top the site.

- By offering a product which requires smaller and less machinery to install.

- By offering a product which has a low carbon footprint in its own right.

- By offering a product which is made to the chainage required.

- By using the latest and most efficient manufacturing techniques.

- By accepting the waste of others for reprocessing.

So that its very little concrete or PVC is actually recycled, and that FRP/GRP cannot be recycled. This document has more information on the relative environmental impact of concrete, PVC or FRP/GRP alternatives to HDPE.

Circular Economy and Recycling

Restore, Reuse, Repurpose

- Infrapipe and Ecopipe are proud of their commitments to sustainable manufacturing. Ecopipe manufactures its culvert pipes using recycled materials such as post- consumer recycled HDPE (shampoo bottles and plastic containers etc.), recycled HDPE milk bottles and reprocessed HDPE by-products from civil pipe manufacturing.

- We are an environmentally friendly company committed to sustainability and strive to ensure minimal waste is maintained throughout our HDPE pipes’ production while consistently meeting our quality standards.

Our Recycling Process

IN PARTNERSHIP WITH REPLAS

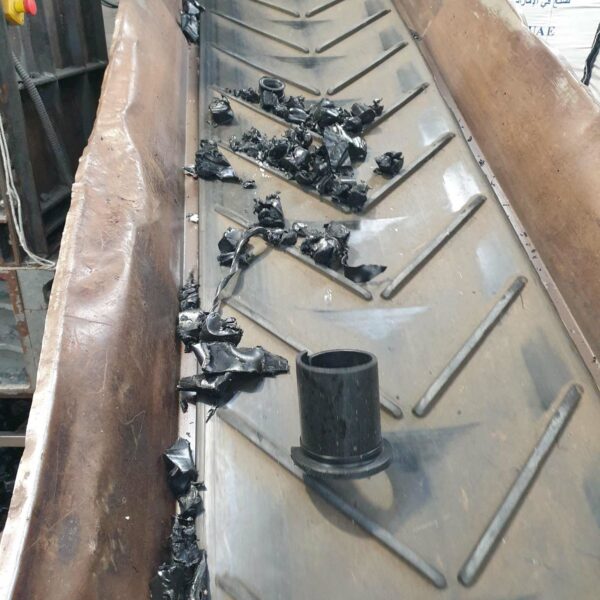

STEP 1: SORTING AND PREPPING

This stage is essential to ensure the plastics are not too large for the machines and remove any foreign matter that may be present.

STEP 3: EXTRUSION

Once the material has been reduced to the appropriate size, it goes through an extrusion process.

STEP 4: COOLING

After the material has been through the extrusion process, it is fed into a water bath for cooling.

STEP 5: DRYING

After the extruded material has been through the water bath for cooling, it goes into a drying process.

STEP 6: MATERIAL IS STORED

Reprocessed material is stored and bagged.

In partnership with REPLAS, based on location, we accept clean HDPE pipes to be dropped off as part of our sustainability efforts, striving for minimal wastage and continuous product stewardship.

As part of this initiative, we welcome Auckland customers to contact us with any enquiries so we can continue to ensure HDPE products avoid going to landfill. We want to help take the HDPE off your hands and contribute to a more sustainable future!

Please fill in the form attached below to arrange drop-off.

INFRAPIPES'

COMMITMENT TO THE SUSTAINABLE DEVELOPMENT GOALS

In line with the United Nations, Infrapipe is committed to following the ‘Sustainable Development Goals’ designed to combat social, environmental, and economic issues.

GOAL 3

GOOD HEALTH AND WELLBEING

Promoting the health and well- being of the individuals who work at Infrapipe is central to meeting sustainable development needs and having a healthy business culture. Infrapipe provides a strong team environment with a support network for all who need it.

GOAL 8

DECENT WORK AND ECONOMIC GROWTH

Infrapipe is committed to providing sustainable economic growth and an inclusive working environment for all. Infrapipe continuously looks after all their staff through working conditions such as encouraging a healthy work-life balance, providing training, and a decent living wage to employees.

GOAL 12

RESPONSIBLE CONSUMPTION AND PRODUCTION

Infrapipe is dedicated to its strong recycling initiatives built on promoting a circular economy where materials and products do not have to have an end life. Committing to this framework ensures the efficient use of resources and sustainable consumption, which is key to the livelihood of future generations.

GOAL 13

DECENT WORK AND ECONOMIC GROWTH

In a strong effort to mitigate climate change, Infrapipe’s pipes are built with a lifespan of more than 100 years and are 100% recyclable. We place a great effort on minimising the wastage, so at Infrapipe we have strategies implemented to ‘do our share’ in facilitating sustainable economic growth and minimising the end material and product that ends up in landfill.

United Nations. (2023). Take Action for the Sustainability Development Goals. Sustainable Development Goals. https://www.un.org/sustainabledevelopment/sustainable-development-goals/

HDPE pipe has a relatively small carbon footprint when compared to iron and concrete pipe. A study conducted in the late 1990s concluded that plastic pipe used in the building, construction and transportation industries required 56,500 trillion fewer BTU’s than iron and concrete/aggregate alternatives.