ENGINEERED CULVERT

Download more information about Infrapipe

- Request a Quote

- Call us: 09 869 3030

- Email: [email protected]

- Office: 3 Averton Place East Tamaki Auckland 2013

This page is for large stormwater applications.

- For small diameter stormwater see DRAINAGE.

- For small rural culverts see SMALL CULVERTS.

- For wastewater applications see WASTE WATER.

- To go direct to the Stormwater Design Manual or Datasheets for INFRAPIPE KRAH, CIVILPIPE or MANHOLES go to the Downloads page.

Like civil pipe, INFRAPIPE can be made to any SN rating to suit the client needs – reducing cost. Typically, culvert fall into three categories:

- Minimum cover – the pipe is buried the minimum necessary to contain the water flows – INFRAPIPE supplies SN4.

- Trafficable cover – the pipe is buried under a road, which is supplied as SN8 or SN16 as required.

- Site specific cover – the pipe needs a strength to match the contours of the land, whether natural or artificial (in stopbanks). INFRAPIPE manufactures each pipe to match its load.

Typical capacities

DN(ID) | Cross-sec | Equivalent to | 25% burial | SN4 | SN16 | |||

2 of ID | 3 of ID | OD | Weight | OD | Weight | |||

450 | 158,963 | 300 | 250 | 127,869 | 528 | 78 | 542 | 90 |

525 | 216,366 | 375 | 300 | 174,045 | 603 | 91 | 621 | 141 |

600 | 282,600 | 375 | 300 | 227,323 | 678 | 103 | 720 | 175 |

700 | 384,650 | 450 | 375 | 309,412 | 792 | 142 | 842 | 212 |

800 | 502,400 | 525 | 450 | 404,131 | 892 | 187 | 962 | 263 |

900 | 635,850 | 600 | 525 | 511,478 | 1020 | 257 | 1096 | 329 |

1000 | 785,000 | 700 | 600 | 631,454 | 1120 | 284 | 1196 | 390 |

1100 | 949,850 | 700 | 600 | 764,059 | 1242 | 325 | 1332 | 428 |

1200 | 1,130,400 | 800 | 700 | 909,294 | 1222 | 325 | 1464 | 463 |

1350 | 1,430,663 | 900 | 700 | 1,150,825 | 1546 | 490 | 1596 | 735 |

1500 | 1,766,250 | 1000 | 800 | 1,420,772 | 1696 | 541 | 1776 | 889 |

1600 | 2,009,600 | 1100 | 900 | 1,616,522 | 1796 | 576 | 1878 | 943 |

1800 | 2,543,400 | 1200 | 1000 | 2,045,911 | 2032 | 703 | 2068 | 1609 |

2000 | 3,140,000 | 1350 | 1200 | 2,525,816 | 2232 | 978 | 2308 | 1878 |

2300 | 4,152,650 | 1600 | 1350 | 3,340,392 | 2572 | 1172 | 2634 | 2796 |

2500 | 4,906,250 | 1800 | 1500 | 3,946,588 | 2778 | 1454 | 2842 | 3395 |

3200 | 8,038,400 | 2000 | 1800 | 6,466,089 | 3500 | 2981 | Ask | |

Life of the asset

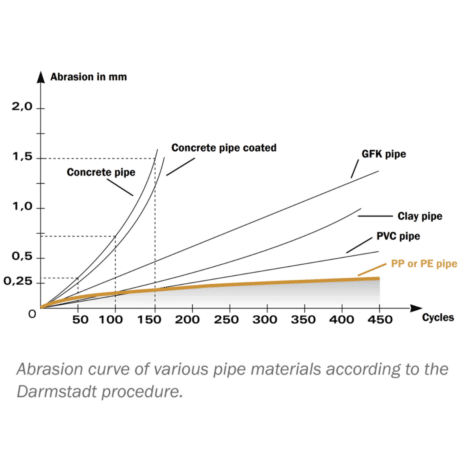

An HDPE stormwater pipe has the best asset life – and Whole Life Cost – for the following reasons:

- Abrasion – as per the Darmstadt test below, the life of HDPE is 280% longer than concrete.

- Chemically inert (see resistance chart here).

- Biologically inert, inedible for microbes and impervious to biofilms.

- No end of life disposal cost – INFRAPIPE is fully recyclable.

- No maintenance required.

- High resistance to impact damage.

- Modification or repair is fast and economical.

- Seismic resistance is the best of any option – as proven in the 2011 Japanese earthquake.

These studies and meta-study confirm the life of HDPE as 100+ years.

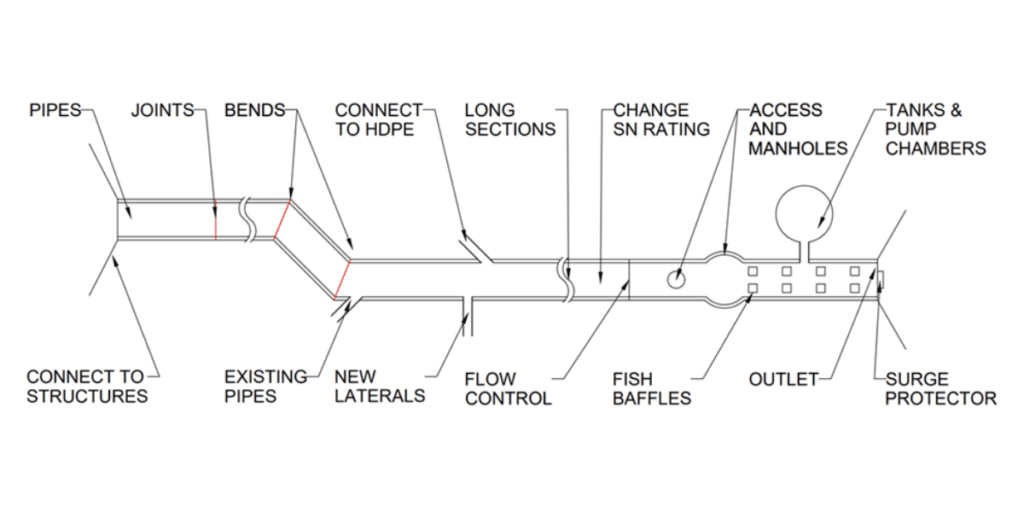

Components of a culvert or stormwater pipeline system

Many culverts are just plain tubes, but for a growing number of applications the pipe is the backbone but not the entirety of a stormwater management system. For full details read this document INFRAPIPE Design Manual for Stormwater because INFRAPIPE can incorporate any of the elements shown below:

And do so quickly, effectively and economically – and INFRAPIPE will even handle the design for you. Submit the plan and they can return a file with what connections need to be done where, because there are less connections with INFRAPIPE!

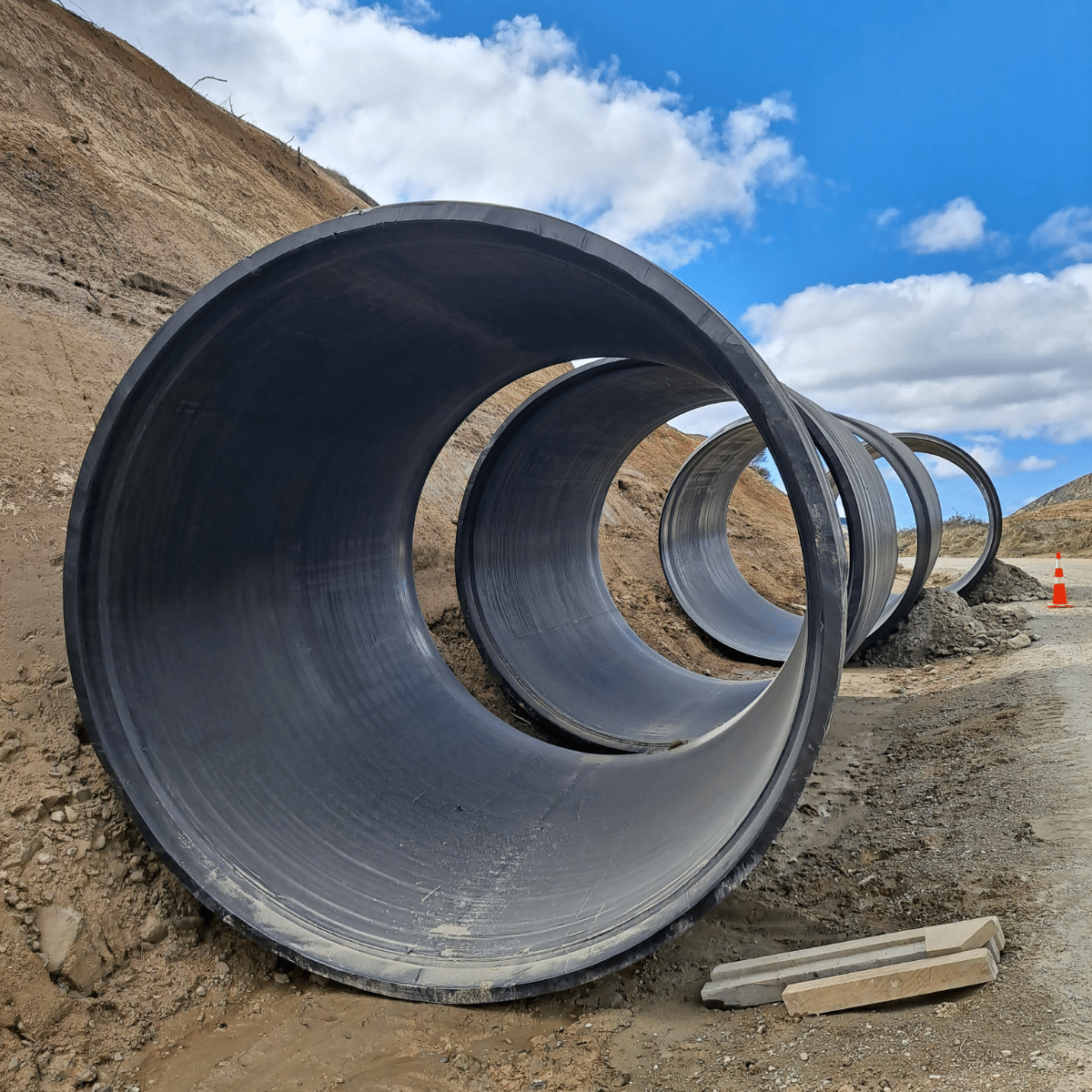

Ease of installation

It is impossible to overstate the value of ease of installation for culvert projects. Here are some of the reasons that time is of the essence:

- Less time = less water – from the ground, the sky or the existing channel.

- Less digger time = less diesel, less servicing.

- Less staff time = less costs.

- Less P & G and site costs.

- Less time on site = less problems!

Why is INFRAPIPE the easiest solution to install:

- Pipes come in 5.8m or 11.8m lengths – joins reduced by 58%.

- Pipes fit easily – they are machined to fit.

- Pipes are six times lighter than concrete so they are easy to manoeuvre and easy to join.

A 600mm class 2 concrete pipe has an effective length of 2440mm and a weight of 663kg.

An SN4 INFRAPIPE has an effective length of 5800mm and a weight of 97kg.

Weight per metre – INFRAPIPE 16.7kg Concrete 271 kg

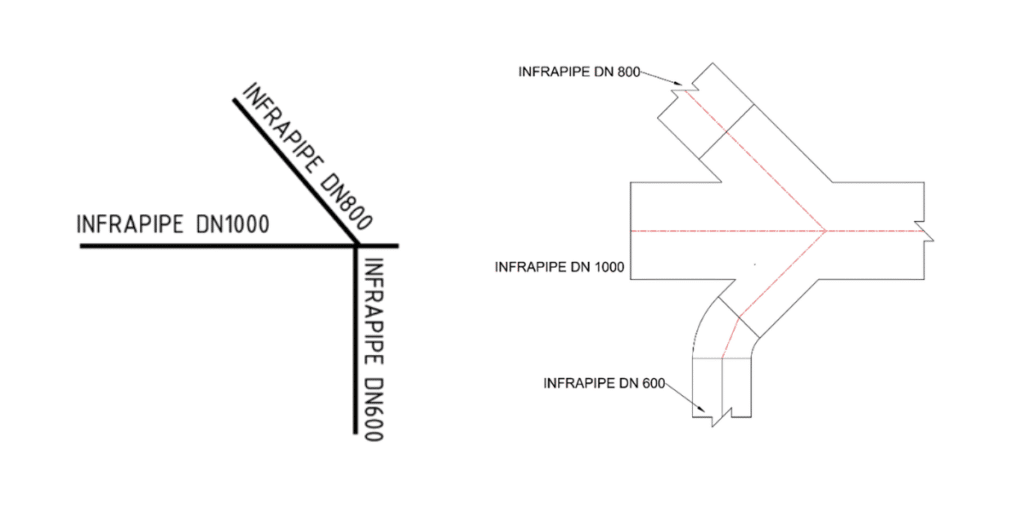

Bends and other modifications

HDPE is easy to cut, easy to weld and completely sealed and homogenous once modified. This enables the designer to accommodate a range of functions such as:

- Angled entry so that an inflow can be received

- Vertical bends so that flow can be further directed once on the lower side of an embankment or hill, moving the outflow away from the critical areas.

- Horizontal bends to take the most appropriate route

- Horizontal bends to improve the converging angle of connections and maximise hydraulic efficiency

Therefore – culverts do not need to be straight!

Traditional stormwater design, driven by the constraints of concrete, relies on manholes for changes of direction and draws straight lines between them. INFRAPIPE ![]() culverts can easily add bends of any angle at any point to allow culverts to follow the lie of the land, skirt around obstacles or other services and take the most economical path. This has the following benefits:

culverts can easily add bends of any angle at any point to allow culverts to follow the lie of the land, skirt around obstacles or other services and take the most economical path. This has the following benefits:

- Less pipe length.

Therefore less excavation.

- Less pipe depth (and hence strength).

Therefore less excavation.

- Less manholes.

Therefore less excavation.

- Less work on connections.

- Smaller site footprint, easier access.

- Less remediation.

Environmental protection

INFRAPIPE can incorporate fish baffles or ladders, or any other protections required for the flora and fauna of New Zealand. In addition, scour blocks or surge protectors can also be fitted in the factory or onsite.

Connections

INFRAPIPE manufactures manholes from the same ![]() product. They are completely customisable and available in any diameter and any height and with connections located at any invert, of any type and any grade. Manholes can even be configured after site survey and despatched the next day, to get perfect alignment of connections.

product. They are completely customisable and available in any diameter and any height and with connections located at any invert, of any type and any grade. Manholes can even be configured after site survey and despatched the next day, to get perfect alignment of connections.

BUT – INFRAPIPE does not need a manhole for every connection. Pipes can be connected in any angle or configuration and, as in the example below, the lateral can be angled as part of the connection to minimize the hydraulic loss from turbulence when flows join – converging angles as small as 11 degrees are possible.

In addition, INFRAPIPE can add access risers (typically 600mm or 1000mm) rather than a manhole to facilitate access for people or remote sensing equipment.

Box culverts & Relining

INFRAPIPE can be used to reline existing collapsed box culverts or circular pipes. The variable strength of INFRAPIPE means it can often be an alternative for a box culvert.

Sustainability

- INFRAPIPE products are fully recyclable.

- All production waste is reprocessed.

- There are no harmful or excessive byproducts from manufacture, all that is used is chilled water.

- The reduction in weight and hence freight reduces the carbon footprint of delivery to site.

- The reduction in time to install and installation machinery also reduces carbon footprint.

Abrasion resistance

A 10mm concrete pipe abrades at 0.7mm/100kcycles. For an 8mm inner layer INFRAPIPE, the abrasion is 0.2mm/100kcycles. The life of the concrete therefore is 14,280 kcycles, the life of the INFRAPIPE is 40,000 kcycles.

The Darmstadt procedure, which has been the standard for abrasion testing since the 1960s, simulates the abrasion and resulting wear of liners and pipes that would occur in actual operating conditions by tilting a pipe section containing a mix of sand, gravel and water through 22.5degrees above and below the horizontal for at least 100,000 cycles. The results for PP or PE pipe show a greater resistance to abrasion and hence operating life.

Inquire about factory seconds

Get a quote for your culvert pipe today!