CIVILPIPE - DRAINAGE

- Best resistance to abrasion – over twice as long as equivalent concrete pipes.

- Superb hydraulic performance.

- Extremely strong.

- Good chemical stability.

- Safe when installing due to its lightweight and flexible nature.

- Less transport costs and install costs.

- Quick to install – laying in 6m lengths.

- Bends allow for the most direct routes and reduce the need for manholes.

- Accompanied by a full range of fittings.

- Can be connected to any existing or potential pipe or manhole.

- Can be used in any soil conditions with a 100 year life.

- Completely recyclable.

Download more information about Infrapipe:

- Request a Quote

- Call us: 09 869 3030

- Email: [email protected]

- Office: 3 Averton Place East Tamaki Auckland 2013

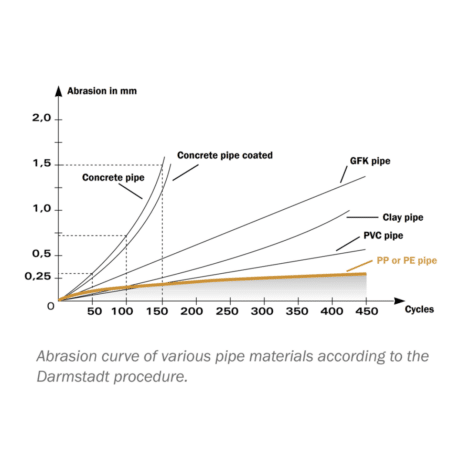

Abrasion Resistance

Polypropylene or polyethylene have the optimum abrasion resistance of any pipe material as proven in numerous tests:

The Darmstadt procedure, which has been the standard for abrasion testing since the 1960s, simulates the abrasion and resulting wear of liners and pipes that would occur in actual operating conditions by tilting a pipe section containing a mix of sand, gravel and water through 22.5 degrees above and below the horizontal for at least 100,000 cycles. The results for PP or PE pipe show a greater resistance to abrasion and hence operating life.

A DN600 will abrade in 13,500,00 cycles. For concrete, even though it is significantly thicker, the pipe will be completely abraded after 5,600,000 cycles.

The above comparison is only for the inner of the CIVIL PIPE twinwall, the outer layer would still be intact.

Performance

HDPE is extremely smooth and the hydraulic performance using these pipes and fittings can be calculated as follows:

https://www.krah.net/en/news/latest-news/276-hydraulic-calculation-of-pe-pressure-pipes

With a Manning’s roughness coefficient of 0.009 compared to concrete’s 0.013 (before abrasion), it is now widely understood that PP/HDPE has the best hydraulic performance.

Strength

PP is flexible and strong and can endure significant elongation before failure. It is not friable like concrete (can chip easily) nor is it brittle like PVC. Products are tested in INFRAPIPE’s laboratory for their resistance to deflection.

Chemical resistance

PP/HDPE are highly inert and immune to biological infiltration. Few materials offer better overall chemical resistance to corrosive acids, bases and salts. Also, PP/HDPE is unaffected by bacteria, fungi or even aggressive naturally occurring soils. Even hydrogen sulphide, the scourge of concrete pipes, has no effect on HDPE. It also provides the lowest biofilm formation potential of all the common water pipe materials in use today.

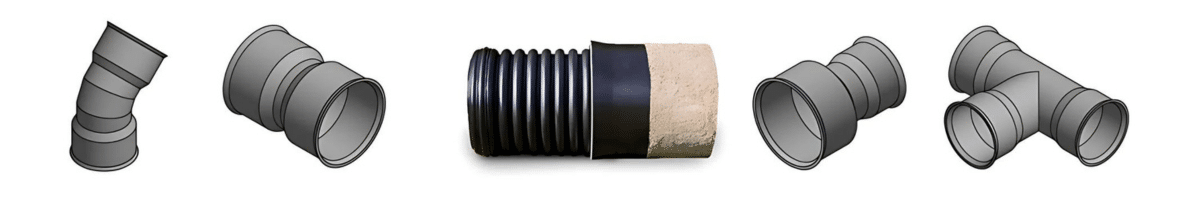

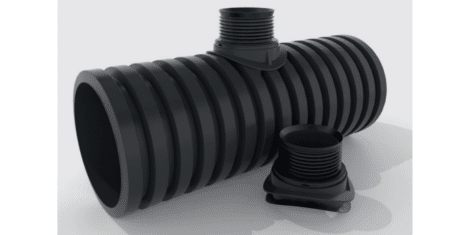

Connecting with fittings

CIVILPIPE can be connected with a variety of fittings listed below. For unusual requirements, custom-made fittings can be fabricated. Fittings have all female sockets and come with a rubber ring for each socket. Screw cap & base, reducing T junctions and reducing Y junctions are available on request. Other fittings are either STD (standard, some quantities held in stock) or POA (Price On Application).

Fittings availability

DN | T Junction | Y Junction | Coupler | Manhole Connector | End Cap |

200 | POA | POA | POA | POA | POA |

225 | STD | STD | STD | STD | STD |

300 | STD | STD | STD | STD | STD |

375 | STD | STD | STD | STD | STD |

450 | STD | STD | STD | STD | STD |

525 | POA | POA | POA | POA | POA |

600 | POA | POA | POA | POA | POA |

800 | POA | POA | POA | POA | POA |

1000 | POA | POA | POA | POA | POA |

Installing or retrofitting smaller laterals

Installing laterals of 100 or 150mm diameter is best achieved using Fernco fittings. For 100 and 150mm laterals, the twin-wall saddle is ideal.

Installing larger laterals

Where a pipe of greater than 150mm is to be introduced, reducing T junctions or reducing Y junctions can be used and are a standard item up to pipe DN450.

Retrofitting laterals

The most economical and efficient way to retrofit a lateral is with the Fernco Storm-T fitting:

Installing or retrofitting larger laterals or onto larger pipes

If the above options do not suit the diameters of the lateral or the main pipe, then a connection can be achieved in one of two ways:

- An interface with a Krah product which can then be custom-made to receive the lateral

- An interface with a manhole which then joins the pipes

Half-lengths & further products

- Half-lengths (3m) for use in short runs or trench shields will be available later in 2024.

- Endless (no socket) lengths will be available in 2025 in sizes DN100-600

- Double sockets will be available in 2025 in sizes DN100-600

Maintenance & modification

- Nil maintenance of this product is required.

- For modifications, contact Infrapipe who can advise on the best way to achieve this.

Care of the product and maintaining your warranty

- For full details on how to care for the product read Infrapipes Guide to Maintaining your warranty.

- Due to the wall thickness of this product, HDPE welding is not recommended.

- In the event of damage during or after installation, repairs can be conducted by cutting out the damaged section and using shear bands with a new section of pipe as shown below. For further advice, contact Infrapipe.