Technical

- Request a Quote

- Call us: 09 869 3030

- Email: [email protected]

- Office: 3 Averton Place East Tamaki Auckland 2013

Abbreviations & Definitions

The pipe world uses a number of definitions, clarified here:

DEFINITION | MEANING |

DN | Nominal Diameter - how the pipe is known. For INFRAPIPE this is also the ID. |

ID ( & OD) | Internal Diameter. INFRAPIPE refers to the ID of its pipes; some competitors market their products under their Outer Diameter (OD) which can imply a capacity 15-20% greater. |

SN | Ring Stiffness - the strength of the pipe. |

PN | Used in pressure applications and expressed in bar, this is the pressure rating of the pipe. Corresponds to SDR for solid wall pipe, ie for PE100 PN16 = 16 bar = SDR11. |

WT | Wall Thickness - the difference between ID and OD. |

SDR | Standard Dimension Ratio - the ratio between WT and OD for solid wall Pipe, ie SDR has a WT of 1/11 the OD. |

PE100 | The standard grade of HDPE used. Sometimes MDPE - PE80 - is used for smaller solid wall pipes as it is more flexible. |

Materials

The table below summarises the performance of different materials with more detail provided after the table:

Requirement | HDPE | Concrete | FRP/GRP | PVC |

Material life | Very good | Satisfactory | Can decay | Good |

Abrasion resistance | Very good | Very poor | Poor | Good |

Seismic performance | Very good | Poor | Poor | Satisfactory |

Hydraulic efficiency | Very good | Satisfactory | Very good | Very good |

Weight | Light | Very heavy | Very light | Heavy |

Homogeneity | Yes | Yes | No | Yes |

Water permeability | No | Yes | Yes | No |

Chemical resistance | Very good | Very poor | Good | Good |

Biological resistance | Very good | Poor | Very poor | Very good |

Recycled in NZ | Very good | Rare | Nil | Rare |

Ease of modification | Very good | Satisfactory | Poor | Poor |

Brittleness | No | Some | Yes | Yes |

Tensile Strength | Very good | Good | Satisfactory | Satisfactory |

Compressive Strength | Good | Very good | Very good | Good |

Deformation Recovery | Good | Nil | Nil | Nil |

Busting some myths

There are a number of incumbent technologies – concrete, FRP/GRP and PVC – that have no desire to be supplanted by HDPE. As a result there are some myths floating around which need to be addressed:

Fat adhesion

There is no evidence that fat or waste adheres to HDPE, nor can any information be found on the issue globally. None of the proofs or studies of the Hazen-Williams nor Darcy-Weisbach equations have identified this as an issue.

Microplastics

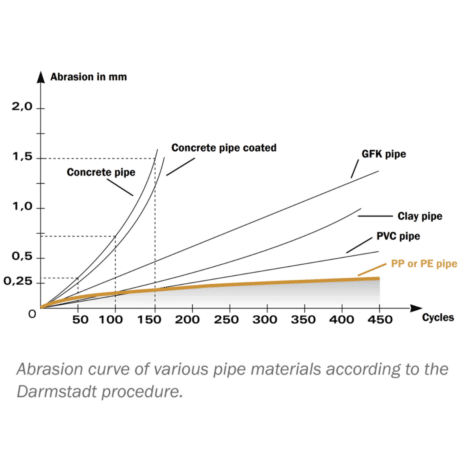

Nor is there any evidence that microplastics emanate from HDPE more than an FRP tank and its epoxy layers or from the PVC pipes that initially handle the waste, in fact as the Darmstadt data below shows, less abrasion must mean less free particles.

Biological adhesion

The evidence shows that HDPE is the most resistant to the formation and adhesion of biofilms, which enable microbial accumulation and invasion.

Temperature

HDPE operates happily in the range of temperatures found in the global environment, and hence is used in the icy wastes of the Arctic and the scorching sands of Egypt (see pics below). It is not suitable for sustained use with liquids over 60C as this can degrade the material, but INFRAPIPE supplies the potable water, waste water and stormwater requirements which are for ambient temperature.

Material Life – Product Life

The latest meta study by TEPPFA (see INFRAPIPE website) confirmed that the expected life of HDPE pipes is well in excess of 100 years.

Abrasion Resistance – Product Life

HDPE has the optimum abrasion resistance of any pipe material as proven in numerous tests:

The Darmstadt procedure, which has been the standard for abrasion testing since the 1960s, simulates the abrasion and resulting wear of liners and pipes that would occur in actual operating conditions by tilting a pipe section containing a mix of sand, gravel and water through 22.5 degrees above and below the horizontal for at least 100,000 cycles. The results for PP or PE pipe show a much greater resistance to abrasion and hence operating life is significantly longer.

Seismic Performance – Product Life

HDPE pipes and tanks have high flexibility allowing them to absorb seismic energy without breaking or cracking unlike more rigid alternatives. The ductile nature of PE allows the structure to deform without breaking, allowing them to stretch and elongate rather than fracture. See this survey of pipes after the Japanese earthquake of 2011.

Hydraulic Efficiency

The smoothness of pipe materials has been established as the Colebrook-White coefficient. Note this takes no account of degradation over time; a pipe with poor abrasion performance will have an even greater loss of performance. A lower figure is more efficient:

Material | Colebrook-White coefficient |

HDPE/PP | 0.0015 |

Concrete | 0.15 |

FRP/GRP | 0.06 |

PVC | 0.03 |

Source: Civilweb

Homogeneity

A material which is protected by an exterior layer is at risk should this sacrificial layer be penetrated through damage or abrasion.

Supporting Terms

Conversion Table

Euroflo™ Size | Actual ID | Infrapipe™ Size |

160 | 150 | 150 |

200 | 180 | 200 |

250 | 220 | 225 |

315 | 280 | 300 |

400 | 350 | 375 |

500 | 430 | 450 |

630 | 530 | 525 |

800 | 640 | 600 / 700 |

1000 | 850 | 800 / 900 |

1200 | 1030 | 1000 |

1550 | 1400 | 1350 / 1500 |

1750 | 1600 | 1600 |

1950 | 1800 | 1800 |

2150 | 2000 | 2000 |

The Romans did a lot of things very very well – including sanitation. Their approach to 3 Waters has set the standards for the last 2000 years. However, that doesn’t mean that we need to stick dutifully with their materials. We have moved from chariots to cars, and from open fires to heat pumps so why persists with concrete pipes when modern alternatives are cheaper, lighter and greener?